Quality Control

Quality control of purchased parts

China has a complete solar inverter and energy storage battery industrial supply chain, rooted in the domestic market. Through continuous comparison, repeated testing, customer feedback, and continuous optimization of suppliers, Lersion New Eneryg can control product quality from the source.

1. Establish a supplier quality file. If the same specification product appears twice in a row, apply to stop purchasing the same specification product from the manufacturer and proceed to the sample delivery process.

2. Supplier quality inspection, arranging personnel to conduct on-site quality sampling at the supplier's factory, coordinating quality with the supplier, requiring improvement on non-conforming items, unifying quality requirements, and communicating inspection methods.

3. Sign a quality assurance agreement to clearly define product quality responsibilities and penalties.

4. Suppliers' products are required to undergo third-party testing. For several commonly used electronic products, suppliers are required to submit a type test report to our company for inspection. The product casing requires a third-party material analysis report.

5. Provide timely feedback on the quality of purchased products to suppliers, and visit production, packaging, and other processes every week to understand the problems that arise during the use of purchased parts, in order to reduce the occurrence of non-conforming products during the process.

Solar products internal process quality

Quality work should start from the "source", which has two parts. One is the "source" of solar porduct workshop processes, such as solar inverter circuit board processes, assembly processes, and packaging processes. The second source is the change of "people". There are many factors that affect solar quality, such as "people, machines, materials, methods, and environment", but the most fundamental factor is "people".

1. Strengthen personnel management, enhance professionalism

1) assign personnel and positions, reduce frequent personnel transfers, and there will always be a familiar process after the transfer, which will have a certain impact on efficiency and quality.

2) Improve professional skills, cultivate host drivers, team leaders, inspectors, improve human management, and improve orderliness (i.e. work in an orderly manner), with a focus on cultivating work habits. 1 The habit of product self inspection, which integrates first inspection, patrol inspection, and self inspection, has problems in every aspect; 2 Orderly placement of products is not only neat and aesthetically pleasing, but also reduces quality hazards;

3) Following an orderly process, reducing verbal communication, where there are tasks, there is a task list, and when there is circulation, there is a change in the process card personnel. Professional inspectors (professional "doctors" and qualified "police"), while assigning personnel and positions, should have a deep understanding of the product and process. Inspectors should not only understand their own process or a workshop, but must consider the inspection based on the entire product and each process before and after.

2.Refine off grid inverter and battery quality assessment

(1) Strengthen quality supervision and assessment of the molding process in the first workshop, and enhance the sense of responsibility of inspectors and operators.

a. The assessment is refined, changing from the original overall assessment of the team to direct assessment to individuals, while increasing the assessment rewards, creating a certain reward gap between good quality and poor quality.

b. Strictly control waste products. During the scrapping process, the warehouse shall register the weight, and the quality department shall also register the weight. The quality department shall supervise on-site when entering the warehouse. The total number of waste products per month is included in the quality assessment.

c. Strengthen self inspection and include any non-conforming issues found during the inspection process in the assessment. Inspection is more of a supervisory function, with clear provisions for non-conforming items and supervision by team leaders and inspection personnel

d. The personal skills of the operators have been improved, and new employees have implemented a team leader's "assistance and guidance" policy, with a specified period of "assistance and guidance". After the expiration of the period, they will be assessed for employment.

e. Inspector responsibility assessment, improving inspection intensity through supervision and assessment, and organizing quality awareness training. Conduct a monthly morning meeting of the production team to promote and implement quality issues, summarize the quality situation of the previous month, and propose improvements to the quality issues of the work bench. And organize quality awareness training with the themes of "zero defect quality management" and "doing a good job at once"

(2) Hold a quality analysis meeting to focus on phased quality issues, analyze the reasons, develop corrective and preventive measures, and post public notices on the preventive measures.

(3)Strengthen the management of special orders, enter the quality control of special orders, and arrange dedicated personnel to track according to sales department orders. Archive after the order is completed.

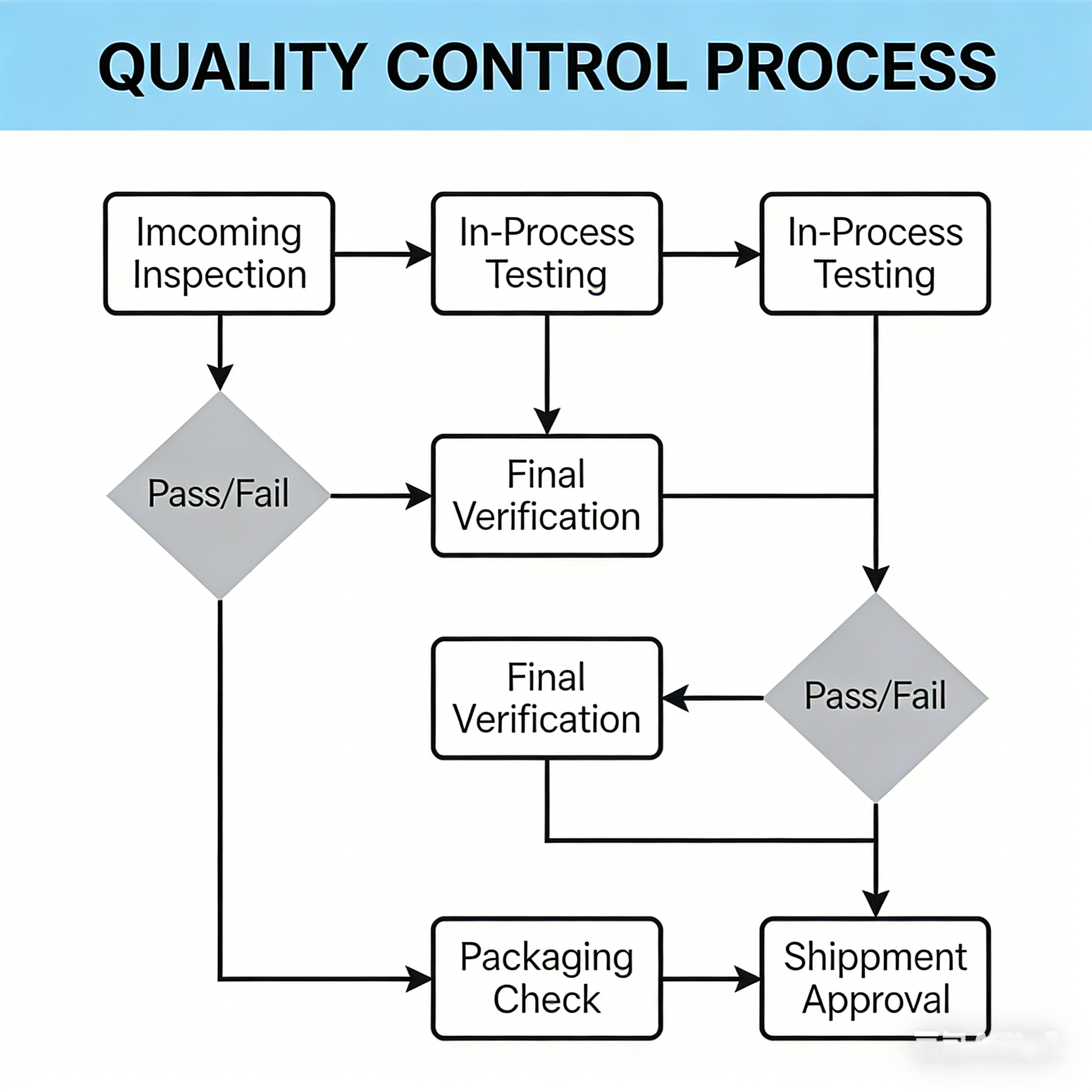

Solar inverter and battery quality control system

ISO9001-2015 standard training and learning, organize quality system standard learning, and study the terms, content, file format, record numbers, etc. of the quality system. And determine the system administrators of each department to conduct internal audits of the company's system and generate audit reports.